Services

- Home

- Services

Explore our best-included AI and Robotics services

Assembly Lines

An assembly line is a production process whereby the manufacture of a good is a sequence of steps completed in a pre-defined sequence. These are the most commonly used mass production method. Assembly lines reduce labor costs because unskilled workers are trained to perform specific tasks rather than build an entire product unit.

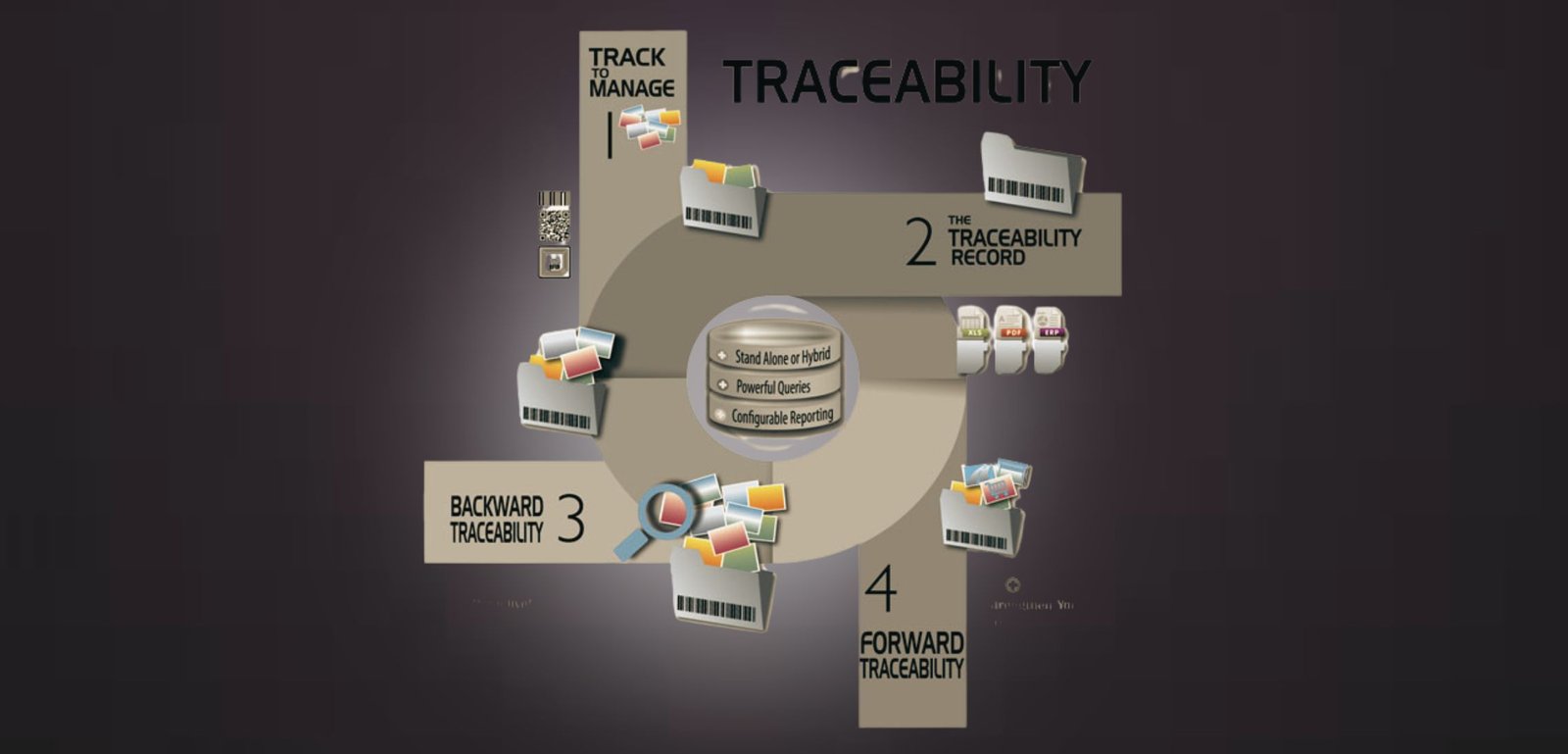

Traceability & Data Management Systems

Traceability is the ability to trace all processes from procurement of raw materials to production, consumption and disposal to clarify when and where the product was produced by whom. In the manufacturing industry, traceability refers to recording essential information such as manufacturers, suppliers and distributors.

Leak Testing Applications

Leak Testing Application offers a comprehensive solution to detect and address leaks, ensuring that your products meet the highest quality standards & regulatory requirements.

Vibratory Systems

Our comprehensive range of Vibratory Systems is designed to optimize your production processes, enhance throughput, and ensure precision in every operation.

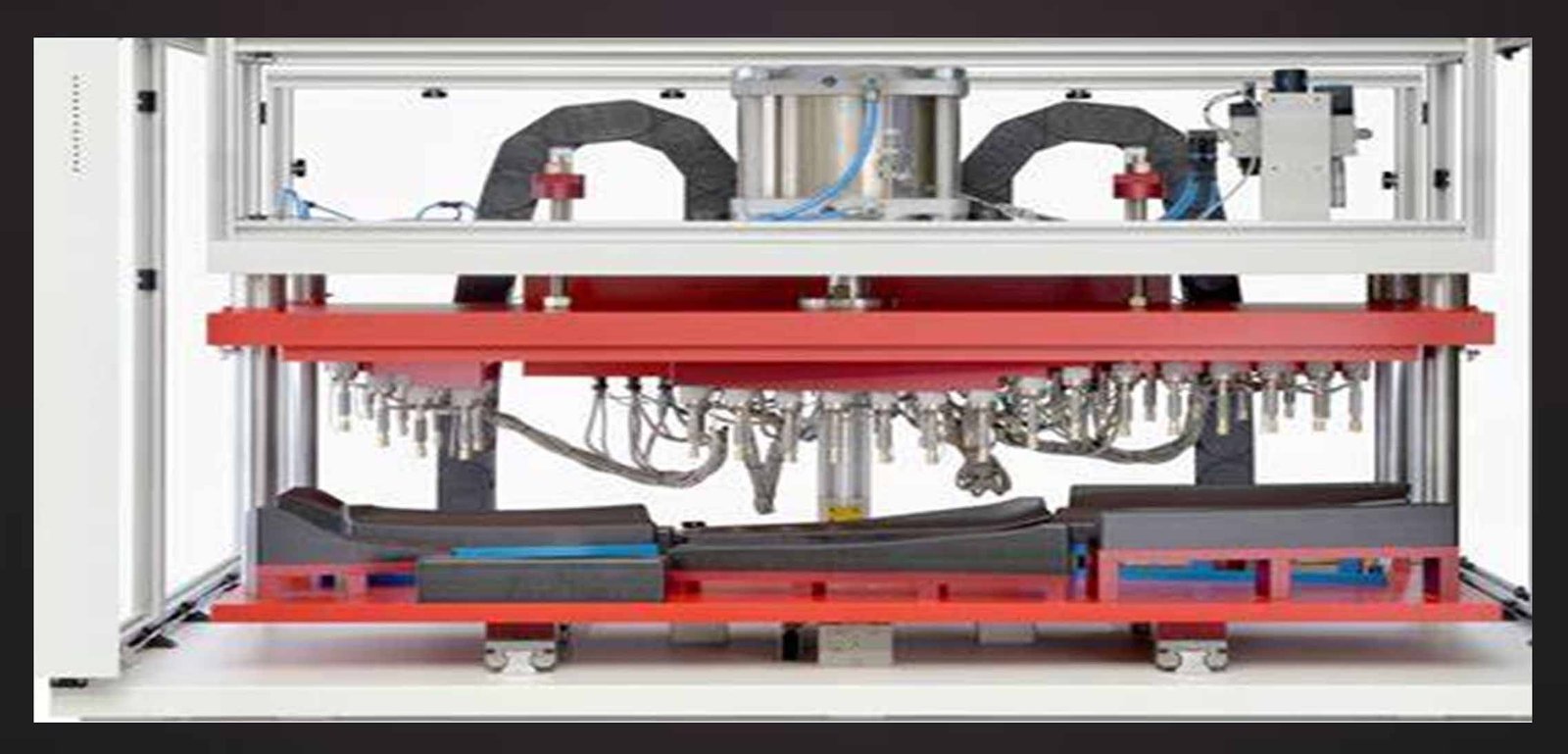

Heat Staking Applications

Heat Staking is a joining technology to join two or more parts together where at least one is made out of plastic. The process is used to melt & deform the plastic material using heat & force at a set process time. De-forming the plastic is achieved by heating it above the glass transition temperature & apply pressure

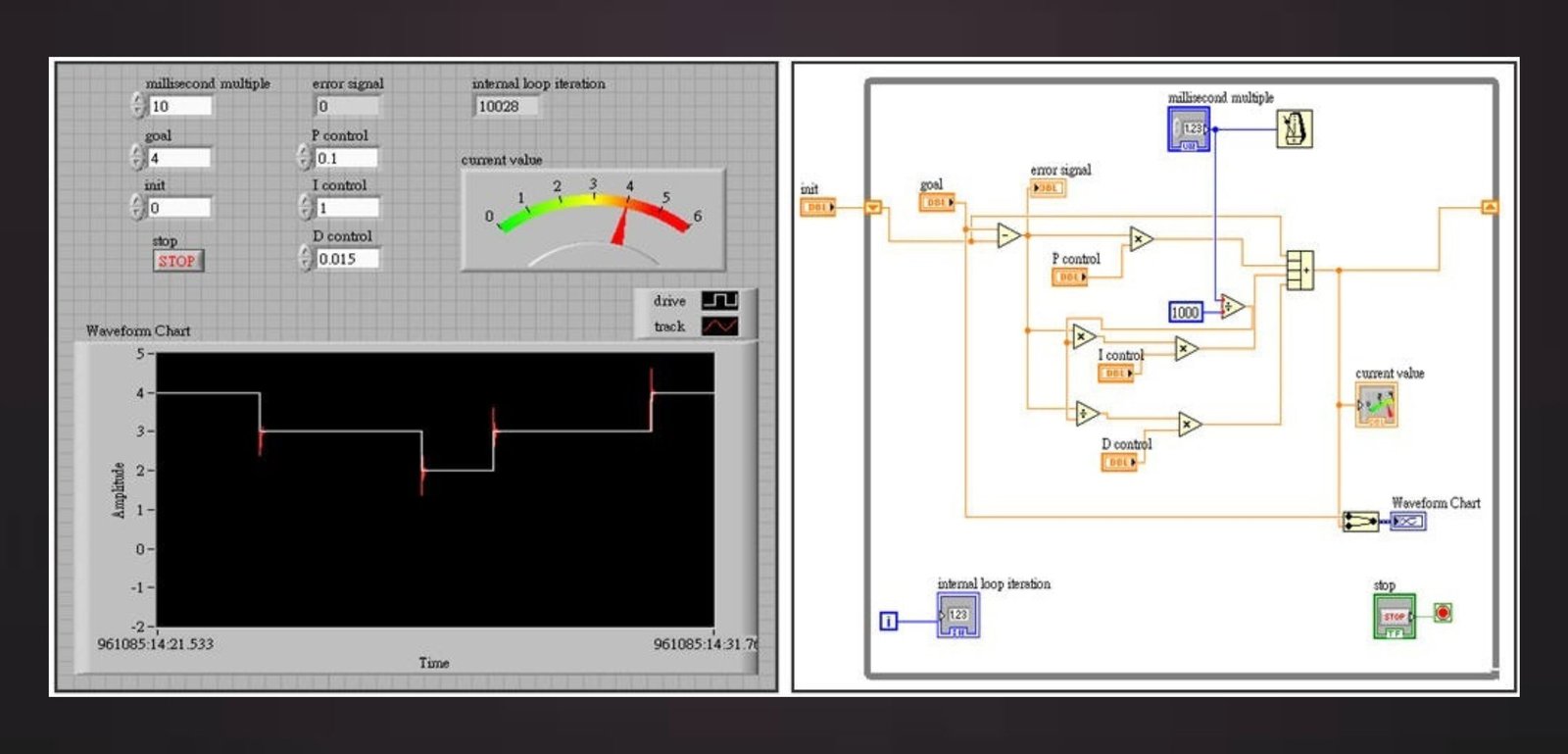

Labview & PLC Programming

LabVIEW is widely used in test & measurement systems, automation, data acquisition & control . Graphical Programming Technique is a technique where VISUAL BLOCK Connections are used to code instead of text which makes it easy for non-coders to implement algorithms. These are used to integrate the whole system

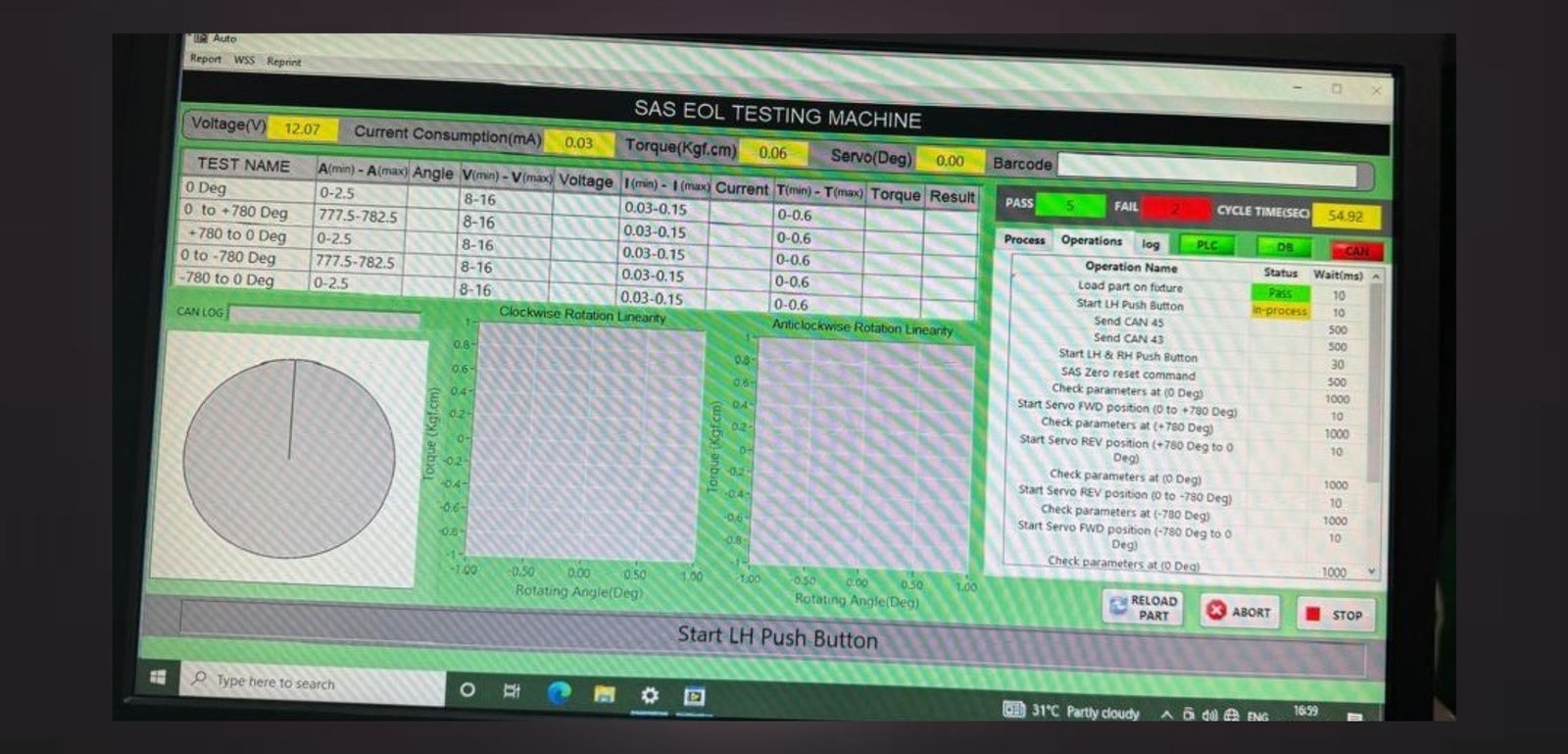

CAN & LIN System Integration

Both CAN and LIN are message-based communication protocols, meaning that data is transmitted in discrete messages or frames. Both use serial communication methods, which are efficient for long cable runs and help reduce electromagnetic interference

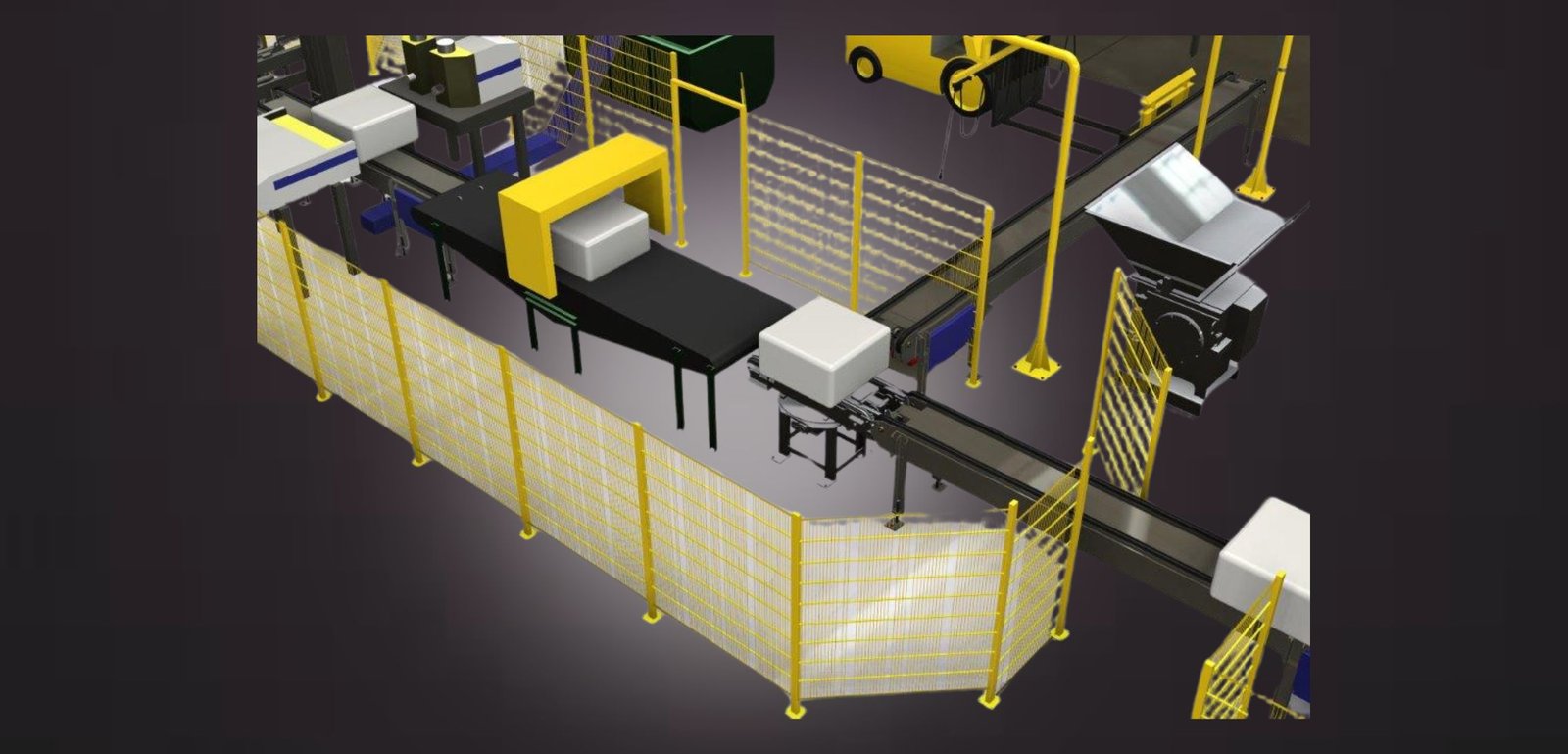

Material Handling Solutions

Material handling refers to the movement, protection, storage, and control of materials and products throughout manufacturing, warehousing, distribution, and the overall supply chain. An optimized material handling system is essential for efficient logistics and operations

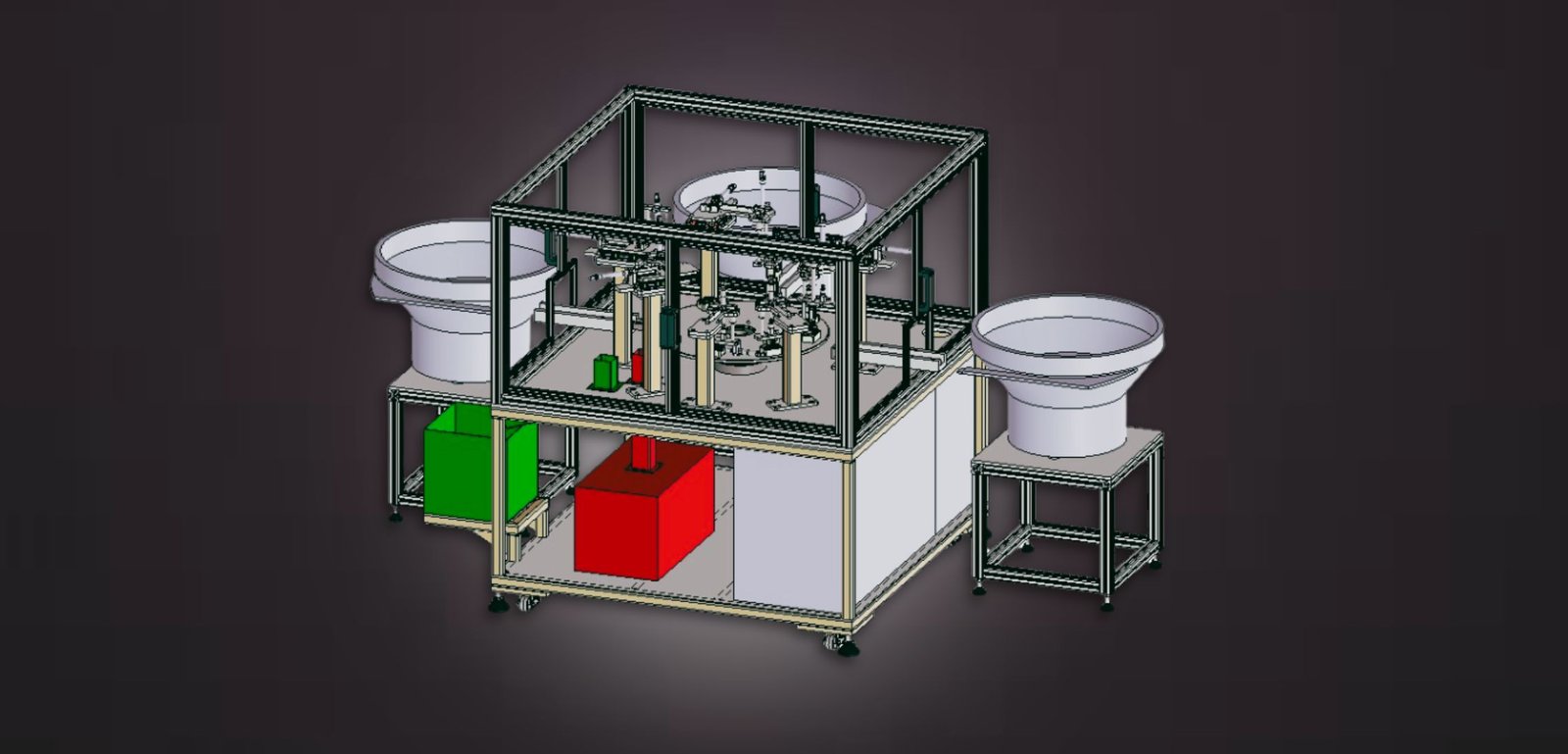

Assembly Automation

Assembly automation is the process of building products on a machine using controlled operations with optimized speed and precision. Automation is precise and repeatable. It ensures the product is manufactured with the same specifications and process every time. For many manufacturers, the assembly process can signify one of the highest direct labor costs. These costs can be mitigated through automation. Automated processes lead to tighter process control and higher quality standards while keeping costs down.

Optical Inspection Systems

Optical inspection is a method of quality control. It looks for defects during the manufacturing process. It gathers data that technicians can use to identify the cause of product flaws. Manual visual inspection was the traditional industry standard. Automated optical inspection systems detect flaws and perform assessments without human intervention. They use machine vision and deep machine learning. An automated optical inspection system can go beyond identifying errors. It can recognise trends and make predictions

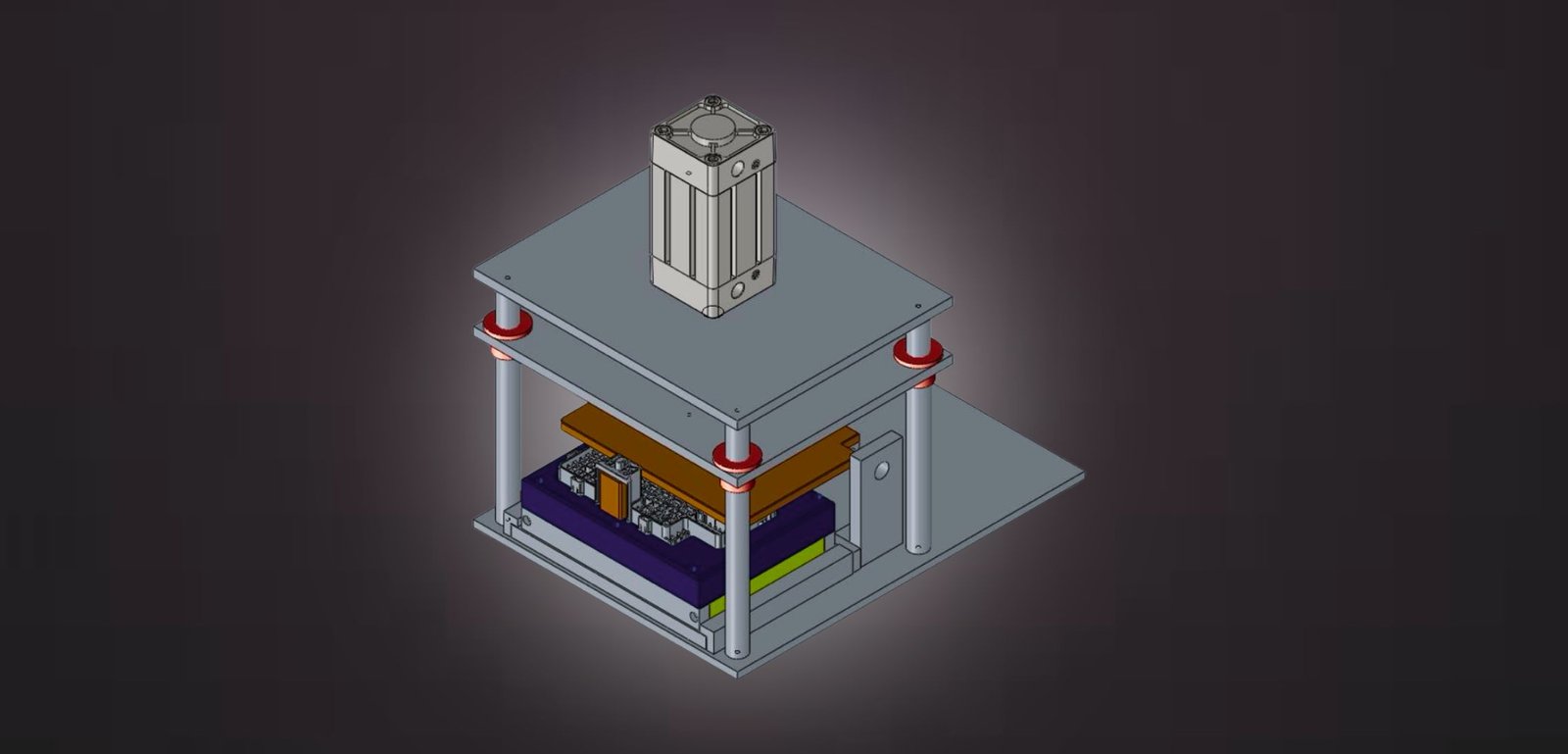

Test & Assembly Fixtures

A fixture is a cavity for locating, holding and supporting a workpiece during a manufacturing operation. Fixtures are essential elements of production processes as they are required in most of the automated manufacturing, inspection, and assembly operations

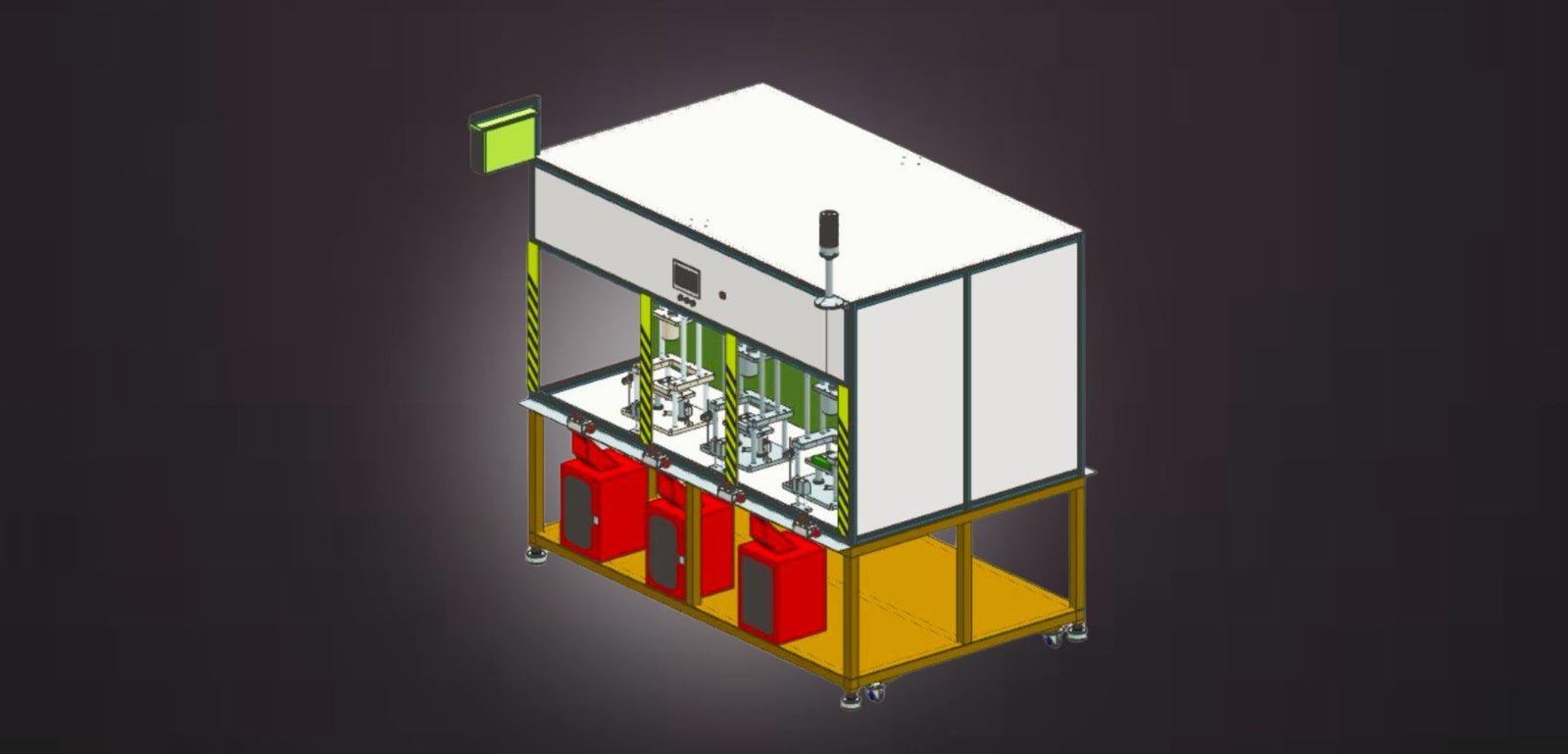

Special Purpose Machines

An Introduction to a special purpose machine, also known as a single-purpose machine or special-purpose machine that has been built to carry out only one task. SPMs can produce larger quantities of products quicker with more efficiency than conventional machines

Conveyorised system

Material handling refers to the movement, protection, storage and control of materials and products throughout manufacturing, warehousing, distribution and the overall supply chain. An optimized material handling system is essential for efficient logistics and operations

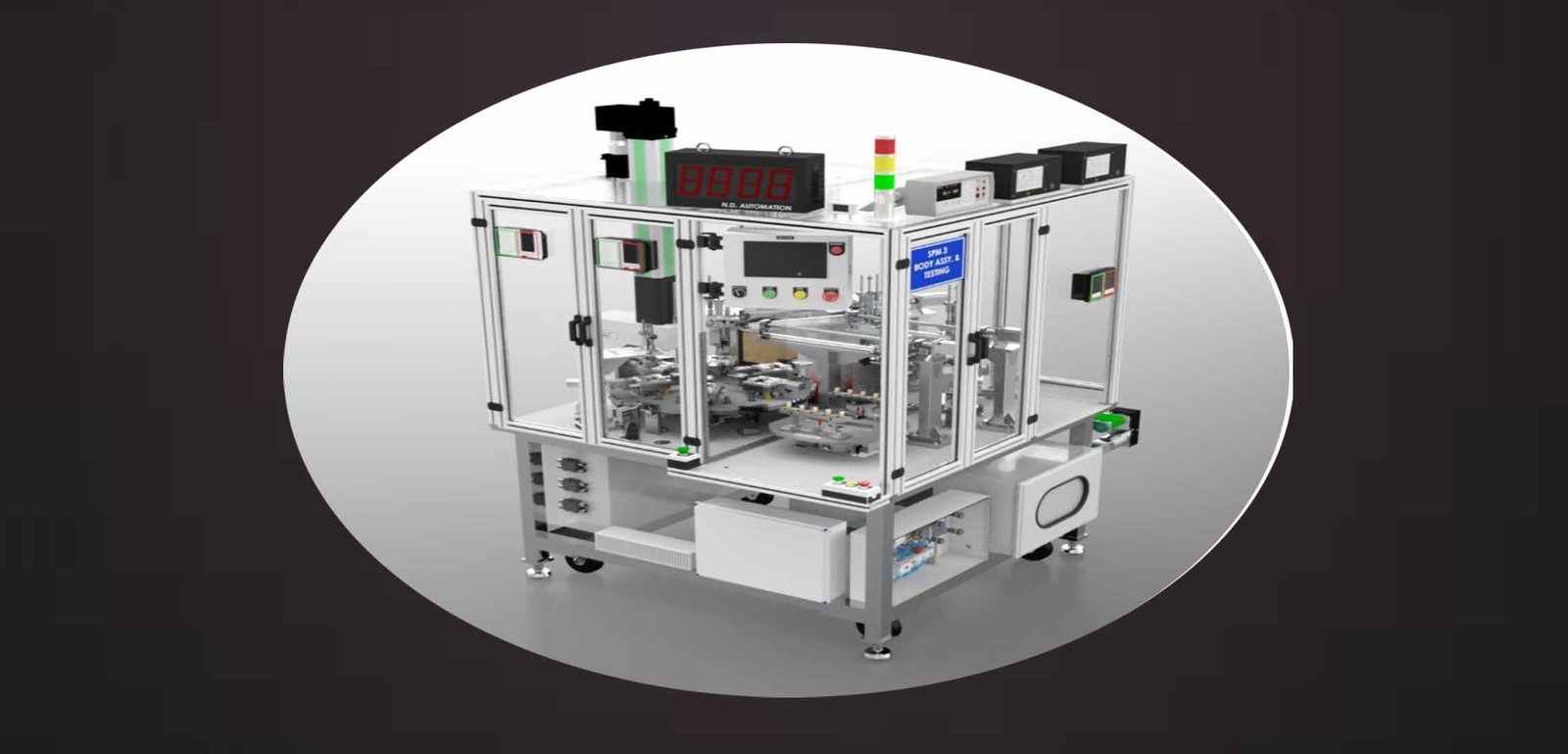

Assembly and Testing Automation

Assembly automation is the process of building products on a machine using controlled operations with optimized speed and precision. Automation is precise and repeatable. It ensures the product is manufactured with the same specifications and process every time. For many manufacturers, the assembly process can signify one of the highest direct labor costs. These costs can be mitigated through automation. Automated processes lead to tighter process control and higher quality standards while keeping costs down.